Navigating Workflow Automation in Dental Laboratories – Challenges, Triumphs, and the EviSmart Paradigm

Executive Summary

The dental laboratory industry stands at a pivotal juncture, compelled by technological advancements and evolving market demands to embrace digital transformation. Workflow automation, once a futuristic concept, is now a critical imperative for labs seeking to enhance efficiency, improve quality, manage costs, and maintain competitiveness. This report delves into the multifaceted landscape of workflow automation in dental laboratories, examining the significant challenges encountered during implementation and the substantial benefits that accrue to labs committing to this transition.

Key challenges identified include substantial financial outlays for technology and more importantly, training; there are complexities of integrating disparate hardware and software systems, managing data quality and security, overcoming human factors such as skill gaps and resistance to change, ensuring robust quality control in automated environments, and addressing scalability concerns. These hurdles are often interconnected, requiring a holistic strategic approach.

Conversely, the advantages of successful automation are transformative. Laboratories can achieve revolutionary gains in efficiency, productivity, and profitability. It is not uncommon to see dental labs grow their revenue by 10-50% without increasing headcount and providing faster turnaround times. Accuracy, consistency, and the overall quality of restorations are significantly elevated, leading to lower remake rates and improved patient outcomes. Furthermore, automation facilitates considerable cost savings through optimized material usage, reduced labor per case, and streamlined administrative processes. Enhanced communication and collaboration with dental clinics emerge as pivotal benefits, fostering stronger partnerships.

EviSmart, an AI-powered dental workflow solution, is an example of how independent systems within the dental ecosystem can be effectively connected. Its modular approach and emphasis on universal compatibility address the pervasive issue of fragmentation, offering tools to automate tasks from case intake and quality control to design and manufacturing preparation.

When assisting labs in their automation journey, common obstacles emerge. These include managing unrealistic expectations, navigating resistance from staff, addressing pre-existing data quality issues, tackling the technical intricacies of integration, ensuring adequate training for new systems, and managing the initial disruptions to established workflows.

Strategic recommendations for dental laboratories include conducting thorough self-assessments, defining clear automation objectives, developing phased implementation plans, prioritizing investments wisely, establishing robust data governance, and, crucially, fostering an automation-ready culture through investment in personnel.

Ultimately, the future of dental laboratories is inextricably linked with automation. Committing to this digital evolution is not merely an operational upgrade but a strategic necessity for sustained growth, enhanced service delivery, and a competitive edge in an increasingly digital dental industry.

Section 1: The Evolving Dental Laboratory: Embracing Digital Transformation

1.1 The Current Landscape: Pressures and Imperatives

Dental laboratories currently operate within a highly dynamic and demanding environment. The pressures are multifaceted, stemming from expectations for ever-higher precision in restorations, significantly faster turnaround times to meet patient and clinician needs, and stringent cost control measures to maintain profitability. Simultaneously, the entire dental industry is undergoing a significant digital shift, largely initiated by dental clinics adopting technologies like intraoral scanners. This trend places an imperative on laboratories to adapt their own workflows to remain compatible and competitive.

Compounding these market-driven pressures are significant operational challenges. Persistent staffing shortages for skilled dental technicians are a major concern across the industry, making it difficult for labs to scale or even maintain current production levels without innovative solutions. Alongside this, rising operational costs, including materials, utilities, and labor, exert continuous pressure on profit margins, making operational efficiency not just desirable but essential for survival. The increasing prevalence of digital impression systems in dental practices means that laboratories must be equipped, both technologically and in terms of skill, to receive, manage, and process these digital files seamlessly.

1.2 Defining Workflow Automation in the Dental Laboratory Context

In the context of a modern dental laboratory, workflow automation refers to the strategic application of digital technologies to streamline, optimize, and, where possible, autonomously execute the sequence of tasks involved in the creation of dental restorations and appliances. This encompasses a broad spectrum of technologies, including sophisticated Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, advanced 3D printers, precision milling machines, and integrated laboratory information management systems (LIMS) or specialized workflow platforms.

The automated workflow typically begins with the digital acquisition of patient data, often through intraoral scans received from dental clinics or via in-house scanning of traditional impressions. This data then flows into CAD software, where technicians, increasingly assisted by AI-powered tools, design the restoration. These digital designs are subsequently transferred to CAM systems that control manufacturing equipment like 3D printers or milling machines to produce the physical object. Beyond the core design and manufacturing processes, automation also extends to post-processing steps, quality control checks, case tracking, communication with clinicians, and various administrative tasks, creating a more cohesive and efficient operational environment.

1.3 The Imperative for Automation: Why Change is Not Just an Option, but a Necessity

For dental laboratories, embracing workflow automation is rapidly transitioning from a competitive advantage to a fundamental requirement for sustained operation and growth. The need to enhance efficiency is paramount; automation directly addresses this by minimizing manual interventions, reducing the potential for human error, and accelerating processes. This, in turn, allows labs to improve collaboration with dental clinics by providing faster, more reliable services.

A core driver for automation is the unyielding demand for consistent quality and predictable outcomes in dental restorations. Automated systems, once properly calibrated and managed, can produce restorations with a high degree of precision and uniformity, reducing variability that can occur with purely manual techniques. This consistency is crucial for minimizing costly remakes and adjustments, thereby improving overall product quality and patient satisfaction.

Furthermore, automation enables laboratories to effectively manage increasing case volumes without a corresponding linear increase in manual labor. This scalability is particularly critical given the widespread and persistent shortages of skilled dental technicians. By automating repetitive and time-consuming tasks, labs can optimize the deployment of their existing skilled workforce, allowing technicians to focus on more complex, value-added activities that require human expertise and artistry.

The impetus for automation is not solely an internal quest for operational excellence. It is significantly influenced by external pressures, particularly the digitization wave occurring in dental clinics. As dentists increasingly adopt technologies like intraoral scanners, they generate digital inputs that require similarly digitized and automated workflows on the laboratory side. Laboratories that fail to adapt to this digital influx risk becoming incompatible with their forward-looking clinical partners, potentially leading to a loss of business and relevance. Thus, workflow automation is not merely an option for improvement but a strategic imperative for survival, growth, and continued integration within the evolving dental healthcare ecosystem.

Section 2: Overcoming the Hurdles: Key Challenges in Dental Lab Workflow Automation

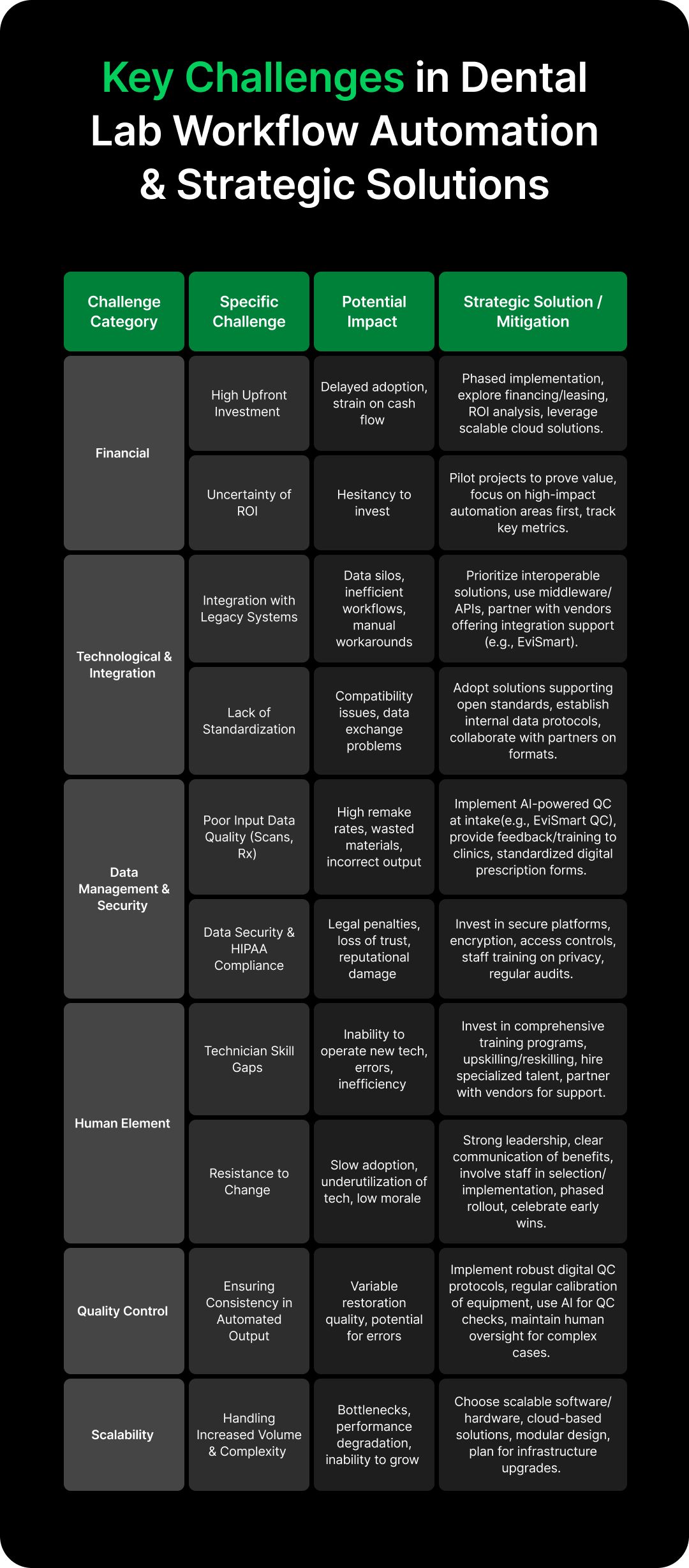

The transition to automated workflows in dental laboratories, while promising significant advantages, is fraught with challenges that require careful consideration and strategic planning. These hurdles span financial, technological, data management, human resource, quality control, and scalability domains.

2.1 Financial Barriers: The Investment Dilemma

One of the most immediate and significant barriers to adopting workflow automation is the substantial financial investment required. This includes high upfront costs for acquiring essential hardware such as high-precision scanners, advanced 3D printers, and multi-axis milling machines, as well as sophisticated software suites for CAD/CAM processes and laboratory information management. For instance, establishing a lean 3D printing-capable dental laboratory can necessitate an initial outlay ranging from $50,000 to $100,000, while more comprehensive, high-capacity automated setups can easily exceed $500,000.

Beyond the initial purchase, laboratories must also budget for ongoing operational costs, including software licenses, material consumables, regular maintenance of complex machinery, and periodic system upgrades to keep pace with technological advancements. The financial commitment extends to training personnel to operate and manage these new systems effectively, which also represents a considerable investment in both time and resources.

For many laboratories, particularly smaller operations with tighter profit margins, the scale of this investment can be daunting. This is often compounded by uncertainty regarding the return on investment (ROI). The financial pressure isn't solely due to the cost of new technology; labs are often already contending with rising general operational costs, such as for materials and utilities. Consequently, the decision to invest heavily in automation requires a robust business case that clearly outlines projected benefits, such as labor cost savings, reductions in material waste, and decreased remake rates. Without a clear, quantifiable path to ROI, or if the payback period seems excessively long, the immediate financial burden can act as a powerful deterrent, leading to hesitancy or delayed adoption. The fear of selecting inappropriate technology that may quickly become obsolete or fail to deliver promised efficiencies further amplifies this investment dilemma.

2.2 Technological and Integration Complexities

The technological landscape of a dental laboratory is often a heterogeneous mix of equipment and software accumulated over time from various manufacturers. A major challenge in implementing comprehensive workflow automation lies in integrating these new digital tools with existing legacy systems and ensuring interoperability between diverse software and hardware components. Studies indicate that over 90% of organizations across industries report difficulties when attempting to integrate AI and automation technologies with their current systems.

The lack of universal interoperability standards and standardized data formats within the dental technology sector can create significant workflow friction and lead to the persistence of data silos. This means that data from one system (e.g., an intraoral scanner) may not seamlessly flow into another (e.g., a CAD design software or a milling machine from a different vendor) without manual intervention or custom-built interfaces. Such integration issues can negate many of the anticipated benefits of automation, reintroducing manual steps, increasing the risk of errors, and adding to the overall complexity of the workflow.

Furthermore, the technological maturity of some AI-driven automation solutions can vary. While some tools are robust and proven, others might still be in earlier stages of development, making their practical integration into demanding, high-volume production environments challenging. The "plug and play" ideal, where new systems seamlessly connect and communicate, is often far from the reality experienced by dental labs. Instead, labs may find themselves managing a patchwork of disparate systems that require considerable effort to orchestrate, undermining the goal of a fully streamlined and automated process. This underscores a critical need for solutions that prioritize and facilitate universal connectivity and data exchange across different platforms and equipment.

2.3 Data Management, Quality, and Security

Data is the lifeblood of automated dental workflows, yet its management, quality, and security present formidable challenges. The principle of "garbage in, garbage out" is particularly pertinent; poor quality input data will inevitably lead to flawed automated outputs, undermining the entire system's reliability and effectiveness. In the dental laboratory context, this often manifests as issues with incoming digital impressions from clinics—which may be incomplete, distorted, or lack clear margin definition—and unclear or ambiguous prescriptions. Ensuring the accuracy, consistency, and completeness of all data inputs is therefore critical for achieving reliable and high-quality results from automated design and manufacturing processes.

The sheer volume of digital data generated and handled by automated labs—including large scan files, complex CAD designs, and detailed patient records—requires robust data storage, backup, and retrieval solutions. Managing this data effectively is an ongoing task.

Data security and patient privacy are of paramount importance, particularly given the stringent requirements of regulations such as the Health Insurance Portability and Accountability Act (HIPAA) in the United States and similar data protection laws globally. The increased reliance on digital systems and interconnected networks inherently expands the attack surface for cyber threats. Indeed, a striking 95% of organizations believe that their increased investment in AI and automation has correspondingly increased their vulnerability to such threats. Protecting sensitive patient health information (PHI) from unauthorized access, breaches, and cyberattacks necessitates comprehensive security measures, including data encryption, secure access controls, regular security audits, and staff training on data protection protocols.

An important aspect of data quality in dental labs is that issues often originate upstream, outside the direct control of the laboratory itself, such as with the quality of scans taken at the dental clinic. While manual workflows might allow experienced technicians to intuitively compensate for minor imperfections in an impression, automated systems are typically less forgiving. Poor input data can lead to significant problems downstream, including ill-fitting restorations and the need for costly remakes. This reality means that automation can starkly expose these upstream quality deficiencies, compelling laboratories to become more proactive in their intake quality control processes and to engage in closer collaboration and feedback loops with their referring dentists to improve the quality of initial data submissions.

2.4 The Human Element: Skill Gaps and Resistance to Change

The successful implementation of workflow automation is not solely a technological endeavor; it is profoundly influenced by the human element. One of the most significant challenges is the prevailing shortage of dental technicians who possess the requisite skills and training to operate, manage, and maintain advanced digital technologies and AI-driven systems. Reports indicate that 53% of organizations experience skills gaps specifically related to the management of specialized computing infrastructure required for such automation. This scarcity of digitally proficient talent can hinder a lab's ability to fully leverage its technological investments.

Concurrent with skill gaps is the common challenge of resistance to change among staff. Technicians who have honed their craft using traditional, manual methods for many years may be apprehensive about adopting new digital tools and workflows. This resistance can stem from various factors, including fear of job displacement as automation takes over tasks previously performed by humans, concern about their ability to learn and master complex new systems (fear of incompetence), or a general skepticism about the benefits of the new technology.

A lack of understanding and education regarding the role and actual benefits of AI and automation can further exacerbate this resistance. If the purpose and advantages of the changes are not clearly communicated, or if staff feel that their expertise is being devalued, adoption rates will likely be low, and the new systems may be underutilized or incorrectly operated.

Addressing these human factors necessitates a significant investment in ongoing training, upskilling, and reskilling programs. This requires not only financial resources but also dedicated time for learning. The "human element" is often the most underestimated component of an automation strategy, yet it is frequently the most complex to manage. While technology can be purchased and installed, transforming mindsets, cultivating new skills, fostering trust in new systems, and encouraging a culture of adaptability requires deliberate, empathetic, and sustained effort, underpinned by strong leadership and effective change management strategies.

2.5 Ensuring Quality Control in Automated Environments

While a primary goal of workflow automation is to reduce human error and enhance the consistency of output, the implementation of automated systems introduces new challenges for quality control (QC). Poorly configured, inadequately calibrated, or insufficiently monitored automated systems can still produce substandard restorations. If the underlying algorithms are flawed or the input data is compromised, automation can consistently replicate errors at scale.

The "black box" nature of some advanced AI algorithms, where the decision-making process is not easily interpretable by humans, can make it particularly difficult to diagnose the root cause of errors or deviations when they occur. This lack of transparency can be a barrier to trust and can complicate troubleshooting efforts.

Consequently, laboratories must develop and implement new QC protocols that are specifically adapted to digital and automated workflows. This includes regular calibration and validation of all digital equipment (scanners, printers, mills), rigorous checks of digital designs before manufacturing, and inspection of final restorations. AI-assisted QC tools are also emerging as valuable assets in this domain. For example, systems like EviSmart QC utilize AI to automatically review incoming digital prescriptions and scans, flagging potential issues such as poor scan quality or incomplete information before these cases enter the production pipeline, thereby preventing errors downstream.

The shift to automation fundamentally changes the focus of quality control. Instead of relying on manual inspection at every stage of a traditionally handcrafted process, QC in an automated environment involves ensuring that the systems themselves are performing correctly, that the data inputs are valid and meet predefined standards, and that the AI algorithms are functioning as expected. Human oversight remains crucial, particularly for complex cases or when deviations are detected, but the nature of this oversight evolves from direct manual intervention in every case to managing, monitoring, and validating the automated processes and their outputs. Technicians may transition to roles that involve setting up QC parameters for automated systems, reviewing flagged exceptions, and performing final quality assurance on high-value or aesthetically critical restorations.

2.6 Scalability Concerns for Growing Labs

As dental laboratories grow and their case volumes increase, the automation solutions they implement must be able to scale accordingly to handle the increased demand and complexity. Scalability is not merely about adding more machines; it encompasses the entire technological ecosystem's capacity to expand cohesively.

The underlying infrastructure, including computing power for CAD software and AI processing, data storage capacity for large digital files, and network bandwidth for transferring data between systems and with clinics, must be sufficiently robust and scalable to prevent bottlenecks as operations grow. Software licenses may need to be expanded, and data management strategies must accommodate ever-increasing volumes of patient and case information.

For Dental Lab Organizations (DLOs) or labs with multiple sites, scalability introduces additional layers of complexity. Ensuring standardization of processes, quality control standards, material usage, and equipment calibration across geographically dispersed locations is a significant challenge that automation strategies must address. Centralized oversight, remote monitoring capabilities, and systems that allow for consistent deployment of protocols across all sites become critical.

The ability to scale effectively also ties back to the human element; managing a larger, more complex automated operation may require more specialized personnel or advanced training for existing staff, linking scalability concerns directly to the ongoing challenge of skill gaps and talent development. Therefore, a forward-thinking automation strategy must consider not only the initial implementation but also the long-term growth trajectory of the lab, ensuring that chosen solutions can adapt and expand without requiring a complete overhaul of the system.

Table 1: Key Challenges in Dental Lab Workflow Automation & Strategic Solutions

This table serves as a crucial reference, offering a structured overview of the multifaceted challenges dental laboratories face when venturing into workflow automation. By categorizing these challenges and pairing them with potential impacts and actionable strategic solutions, it provides lab owners and decision-makers with a practical framework. This approach not only aids in understanding the complexities involved but also acts as a foundational tool for self-assessment and strategic planning. It allows labs to anticipate potential difficulties and proactively develop mitigation strategies, thereby increasing the likelihood of a successful and beneficial automation journey. The inclusion of supporting snippet references lends credibility to the identified challenges and solutions, enabling a deeper dive into specific areas if required.

Section 3: The Automation Advantage: Unlocking Massive Benefits for Dental Labs

Despite the challenges, the commitment to workflow automation unlocks a plethora of transformative benefits for dental laboratories, fundamentally reshaping their operational capabilities, quality standards, and competitive positioning.

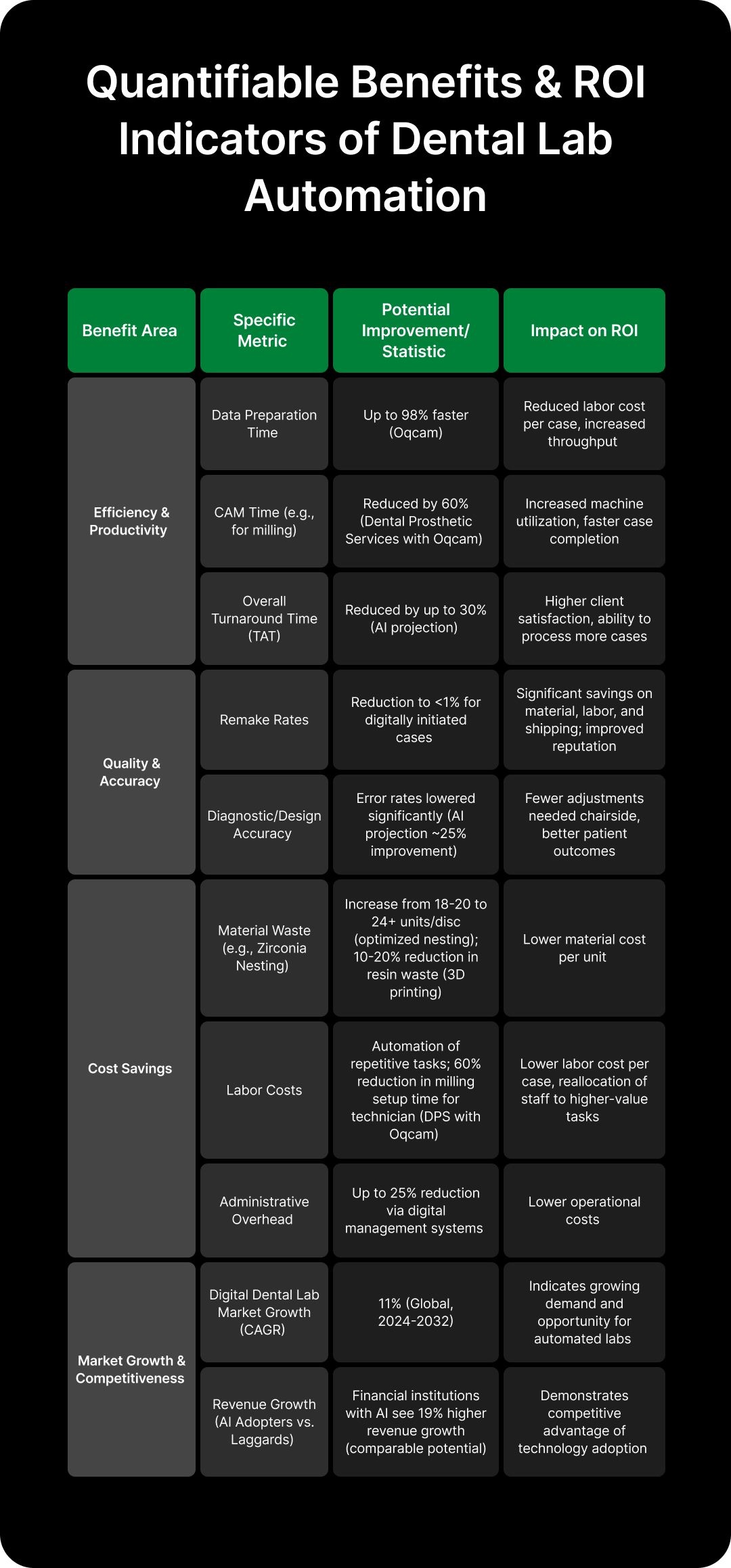

3.1 Revolutionizing Efficiency and Productivity

The most immediate and impactful benefit of workflow automation is a dramatic increase in operational efficiency and overall productivity. Automation leads to a significant reduction in the time and labor spent on manual, repetitive tasks that are common in traditional lab workflows, such as physical model preparation, manual data entry for case management, and the foundational elements of dental design. For instance, automated data preparation software like Oqcam has been reported to achieve up to 98% faster data preparation times compared to manual methods.

Automated manufacturing processes, particularly with 3D printers and milling machines, enable laboratories to extend their production capabilities beyond standard working hours, often running 24/7 with minimal supervision for certain tasks. This continuous production capacity significantly enhances throughput. Streamlined digital workflows, from receiving a digital impression to dispatching the final restoration, mean that labs can process a higher volume of cases with their existing staff, or even a leaner team. Dental Prosthetic Services, for example, reported a 60% reduction in CAM time after implementing Oqcam's automation solutions.

The true revolution in productivity, however, arises not just from automating isolated tasks but from a holistic redesign of the entire workflow. When automation is leveraged to create seamless, interconnected processes that minimize handoffs, reduce idle time, and ensure a smooth flow of information and materials from one stage to the next, the efficiency gains become exponential. End-to-end digital workflows, as envisioned by modern dental technology, allow for an uninterrupted progression from scan acquisition to design, and finally to manufacturing. It is this interconnectedness, often facilitated by integrated platforms, that unlocks the full potential of automation, transforming the lab into a highly efficient production unit.

3.2 Elevating Accuracy, Consistency, and Quality

Workflow automation plays a pivotal role in elevating the accuracy, consistency, and overall quality of dental restorations. Digital impressions, when captured correctly, and subsequent CAD/CAM manufacturing processes generally yield restorations that are more accurate and exhibit a better fit compared to those produced using traditional analog techniques. The precision inherent in digital design software and computer-controlled manufacturing equipment significantly reduces the human error often associated with manual tasks like waxing, casting, and trimming.

Once automated systems are properly calibrated and maintained, they can produce restorations with a high degree of consistency, ensuring that output quality remains uniform regardless of which technician might be overseeing the process on a particular day. This consistency is a hallmark of quality and contributes to greater predictability in clinical outcomes.

A direct and economically significant consequence of improved accuracy and consistency is a substantial reduction in remake rates. Many dental laboratories that have embraced digital workflows report remake rates below 1% for cases initiated with digital impressions, a stark contrast to potentially higher rates associated with traditional methods. Given that each remake incurs additional costs in materials, labor, and shipping, and can strain relationships with clinicians, minimizing remakes has a direct positive impact on a lab's profitability and reputation.

It is important to recognize that automation does not diminish the role of the skilled artisan in the dental laboratory. Instead, it enhances their capabilities. By automating the precise, repetitive, and often tedious aspects of restoration fabrication, technology frees up experienced technicians to concentrate on the more complex aesthetic details, intricate characterizations, and final finishing touches that differentiate superior quality work.

Digital tools also provide superior visualization and planning capabilities, allowing for more meticulous case design. In this synergistic model, automation handles the foundational precision, while human expertise elevates the final product to a higher standard of artistry and clinical excellence.

3.3 Accelerating Turnaround Times (TAT) and Streamlining Case Management

A significant advantage offered by dental lab automation is the acceleration of case turnaround times (TAT), a factor highly valued by clinicians and patients alike. Digital workflows inherently shorten the time required to produce various types of restorations. Some AI-driven automation tools project potential TAT reductions of up to 30%.

One key element contributing to faster TAT is the electronic transmission of case data. Digital impressions and prescriptions can be sent from the dental clinic to the lab almost instantaneously, eliminating the delays associated with shipping physical impressions and models. This immediate data transfer allows the lab to commence work on a case much sooner.

Furthermore, integrated lab management software and workflow automation platforms streamline overall case management. Features such as automated case tracking, intelligent scheduling based on equipment availability and technician workload, and automated notifications to clinicians regarding case status or required approvals significantly improve organizational efficiency. These systems ensure that cases move smoothly through the lab, minimizing idle time and preventing delays.

Accelerated turnaround times represent a powerful competitive advantage for dental laboratories. Clinicians prioritize labs that can deliver high-quality restorations reliably and quickly, as this enables them to provide more timely care to their patients, reduce the number of patient appointments, and manage their schedules more effectively. In a competitive market, a lab's ability to consistently meet or exceed expectations for TAT can be a key differentiator, crucial for attracting new clients and fostering long-term loyalty with existing partners.

3.4 Achieving Significant Cost Savings and Improved ROI

The implementation of workflow automation, despite the initial investment, can lead to substantial long-term cost savings and an improved return on investment for dental laboratories. These savings are realized through various avenues. Firstly, the automation of manual and repetitive tasks significantly reduces the labor hours required per case, leading to lower direct labor costs. For example, the Scinomix ROI calculator for automated labeling systems in labs suggests a potential payback period of around 2.8 years based on labor savings.

Secondly, the shift to digital case submission dramatically reduces expenditure on traditional impression materials and the costs associated with shipping physical models and impressions between the clinic and the lab. These seemingly small per-case savings can accumulate into significant amounts over time, especially for high-volume labs.

Thirdly, advanced CAD/CAM software, particularly for milling and 3D printing, often includes smart nesting algorithms that optimize the placement of multiple restorations within a single block of material (e.g., a zirconia puck) or on a build plate for 3D printing. This intelligent material utilization minimizes waste of expensive raw materials like zirconia, dental resins, and alloys. For instance, optimized nesting strategies can increase the number of single zirconia units produced per standard disc from an average of 18-20 to 24 or more, directly reducing the per-unit material cost. EviSmart Nest is one such solution aimed at reducing material waste.

Perhaps one of the most impactful areas for cost savings is the reduction in remake rates. As previously noted, improved accuracy from digital workflows leads to fewer ill-fitting restorations, directly translating into saved material costs, conserved labor hours that would have been spent on the remake, and avoided repeat shipping expenses.

While not specific to dental labs, broader industry analyses, such as McKinsey's estimate that AI could deliver up to $1 trillion in additional annual value for global banking, suggest the transformative financial potential inherent in automation technologies, which can be extrapolated to niche sectors like dental prosthetics manufacturing.

It is important to understand that the return on investment from automation is not solely derived from direct cost-cutting measures. Enhanced efficiency and productivity also mean increased capacity, allowing the lab to handle a larger volume of cases or take on more complex, and often more profitable, types of restorations without a proportional increase in operational costs. Moreover, the improved quality, consistency, and faster service levels achieved through automation can lead to higher client satisfaction and retention, as well as the acquisition of new clients, all of which contribute positively to the lab's long-term financial health and profitability.

3.5 Strengthening Collaboration and Communication

Workflow automation and the adoption of digital platforms significantly strengthen collaboration and communication between dental laboratories and their clinical partners. Digital systems provide shared environments where dentists and lab technicians can interact seamlessly and in real-time, fostering a more integrated approach to case management and treatment planning.

The ability to share 3D models of scans and designs, along with annotated images and detailed case notes, provides a common visual language that enhances clarity and dramatically reduces the potential for misunderstandings that can arise from purely verbal or written traditional prescriptions. Platforms like EviSmart Comm, for example, offer case-specific messaging tools and allow dentists to review and approve 3D designs directly, often via mobile applications, ensuring that both parties are aligned before manufacturing commences.

This enhanced digital interaction can also lead to improved interprofessional education. As clinicians and technicians collaborate more closely on digital platforms, they gain a better understanding of each other's processes, capabilities, and constraints, which can lead to more efficient and effective teamwork on future cases.

The value of this improved communication is critical and often underestimated. Miscommunication is consistently identified as a major contributor to errors, ill-fitting restorations, and consequently, costly remakes. By providing clear, documented, and easily accessible channels for interaction, digital workflow solutions directly address this core problem. Faster and clearer communication allows for the rapid resolution of queries, swift approval of designs, and proactive problem-solving, all of which contribute to speeding up the entire workflow from case submission to final delivery. Ultimately, these strengthened communication pathways build more robust, trusting, and loyal relationships between dental laboratories and their dental clients, which are invaluable for long-term business success, leading to consistent repeat business and positive referrals.

Table 2: Quantifiable Benefits & ROI Indicators of Dental Lab Automation

This table consolidates quantifiable benefits and statistics, offering concrete evidence of automation's positive financial and operational impact. For dental lab owners, who are primarily business-oriented, linking specific improvements like faster TAT or lower remake rates directly to tangible ROI indicators such as cost savings and increased capacity is crucial. It not only builds a strong case for the initial and ongoing investment in automation but also implicitly suggests key performance indicators (KPIs) that labs can adopt to measure the success and effectiveness of their own automation initiatives. By showcasing these tangible returns, the table serves as a persuasive tool in strategic decision-making regarding technology adoption.

Section 4: Connecting Disparate Systems: The EviSmart Approach to Integrated Dental Workflows

A significant impediment to achieving seamless workflow automation in dental laboratories is the often-fragmented nature of their technological ecosystem. Labs frequently employ a diverse array of hardware—such as intraoral scanners, 3D printers, and milling machines from various manufacturers—and an assortment of software for CAD, lab management, and other specific functions. These components are often not inherently designed for smooth interoperability, leading to operational inefficiencies.

4.1 The Challenge of a Fragmented Ecosystem

This technological fragmentation results in several practical difficulties. Manual data transfer between incompatible systems becomes a common necessity, introducing opportunities for human error and consuming valuable technician time. The lack of cohesive data flow makes it challenging to achieve true end-to-end automation, where a case moves from digital impression to final restoration with minimal manual intervention. This creates bottlenecks, reduces overall efficiency, and can make tracking case progress across different stages cumbersome. The dental industry has historically lacked universal standards for data exchange between different devices and software, further exacerbating this issue. Consequently, there is a pronounced need within the sector for solutions that can act as a "universal connector" or an overarching platform capable of bridging these gaps and integrating disparate systems into a unified workflow.

4.2 Introduction to EviSmart: AI-Powered Workflow Automation

EviSmart emerges as a response to these challenges, positioning itself as an AI-powered dental workflow solution specifically engineered to enhance efficiency and foster collaboration by connecting dental labs, clinics, and potentially manufacturers into a more cohesive ecosystem. A cornerstone of EviSmart's value proposition is its commitment to universal compatibility. The platform is designed to "work with all existing hardware and software, eliminating integration barriers". This capability directly confronts the widespread problem of technological fragmentation in dental labs.

The mission of Evident, the company behind EviSmart, is articulated as making dental care "smarter, faster, and better—for everyone" by developing tools that connect these often-isolated components of the digital dental workflow. By focusing on seamless integration, EviSmart aims to allow labs to leverage their existing technology investments while still achieving the benefits of a more automated and interconnected operation.

4.3 Key EviSmart Modules and Their Role in Automation

EviSmart's platform architecture appears to be modular, offering a suite of tools that address specific stages and pain points within the dental laboratory workflow. This modularity allows labs to adopt solutions tailored to their most pressing needs or to implement a more comprehensive, integrated system over time. Key modules include:

- EviSmart Downloader: This module automates the crucial first step of case intake by retrieving and importing digital impression files from a variety of intraoral scanners and external portals directly into the lab's designated systems. It features customizable download locations and file naming conventions, aiming to eliminate the time-consuming and error-prone tasks of manual downloading and sorting of scan files.

- EviSmart QC: Leveraging artificial intelligence, this module provides automated quality control for incoming digital prescriptions and scans. Based on criteria customized by each lab, it flags potential issues such as missing margins on a scan, misaligned bites, or incomplete and unclear prescription information. The objective is to identify and address these errors at the very beginning of the workflow, thereby reducing the need for costly rework and minimizing back-and-forth communication with the clinic.

- EviSmart CaseEntry: This tool focuses on automating the creation of new cases within the lab's existing management software. It can be configured for customized case scheduling and ensures that case updates are synchronized across the EviSmart platform and potentially integrated with the lab's LMS.

- EviSmart LMS (Lab Management System features): While not a full standalone LIMS, EviSmart incorporates several LMS-like functionalities. These include tools for automated case scheduling, integration with its communication module (EviSmart Comm) for case-specific messaging, automated payment processing features, and the capability to generate customized automated reports for lab management.

- EviSmart CAD: This module is designed to streamline the design phase. It facilitates integration with outsourced CAD design services, enables "touchless" case triage (potentially routing cases automatically based on complexity or restoration type), incorporates AI-powered assistance for common designs like crowns, and allows for customizable QC checkpoints within the digital design process itself.

- EviSmart Comm: A critical component for collaboration, EviSmart Comm provides a dedicated, HIPAA and GDPR compliant platform for case-specific messaging and design approvals between the laboratory and the dental clinic. It integrates with other EviSmart modules and includes a mobile application that allows dentists to conveniently review 3D designs, provide feedback through annotations, or send messages directly to the lab.

- EviSmart Nest: Targeting the manufacturing stage, this module automates the nesting process for both 3D printing and milling operations. By intelligently arranging dental parts on a build plate or within a material puck, it aims to optimize material usage (such as expensive resins, zirconia pucks, and discs) and reduce overall production time. It is designed to be compatible with a wide range of printers, mills, and materials.

The modular design of the EviSmart platform offers laboratories flexibility. They can choose to implement specific modules to address their most acute bottlenecks first, or they can opt for a broader integration of the EviSmart suite to achieve a more comprehensive level of automation. The integration of AI capabilities, particularly in areas like quality control (EviSmart QC) and design assistance (EviSmart CAD), signifies a move beyond simple task automation towards more intelligent workflow management, where the system can make informed suggestions or flag potential issues proactively.

4.4 How EviSmart Addresses Common Lab Bottlenecks

EviSmart's suite of tools is specifically designed to address several common bottlenecks that hinder efficiency and quality in dental laboratories:

- Inconsistent Case Data & Poor Communication: EviSmart QC plays a crucial role by automatically flagging incomplete or unclear prescriptions and identifying poor-quality scans before they enter the main production flow. This proactive approach reduces the chances of errors downstream. Simultaneously, EviSmart Comm provides a centralized and documented communication channel for real-time updates, clarifications, and design approvals between the lab and the clinic, minimizing delays caused by missed calls or emails.

- Manual Data Entry & Case Initiation: The EviSmart Downloader automates the retrieval of scan files, and EviSmart CaseEntry automates the creation of cases in the lab's management system, significantly reducing manual data entry and the associated risk of errors. Testimonials from labs like Concord Dental Lab, stating they have "not missed a single case from the portal since signing on," and Creodent, noting their "workflow has become speedy and efficient," underscore the impact of these automation features.

- Inefficient Design & Manufacturing Processes: EviSmart CAD offers features like AI-assisted crown design and touchless case triage to streamline the design phase. In manufacturing, EviSmart Nest optimizes material utilization and reduces machine time for 3D printing and milling, contributing to faster production and lower material costs.

- Software/File Format Incompatibility: A core tenet of the EviSmart platform is its ability to connect with any existing software and hardware a lab might be using. By providing automatic file conversion and acting as an integration layer, EviSmart aims to overcome the common problem of incompatible systems from different technology providers, allowing labs to maintain their current investments while still benefiting from enhanced connectivity and automation.

The overarching strategy of EviSmart appears to be the creation of an intelligent "operating system" layer that resides above the diverse technological infrastructure already present in many dental labs. This layer facilitates communication and data exchange between previously disconnected systems, enabling them to function as a more cohesive, automated, and intelligent unit. This approach is particularly compelling for laboratories that have already made significant investments in various pieces of equipment and software and are hesitant to undertake a costly and disruptive "rip-and-replace" strategy. EviSmart's messaging, such as "No integration needed, no workflow changes", strongly supports this philosophy of enhancing, rather than replacing, a lab's current technological assets.

Table 3: EviSmart's Solutions to Common Dental Lab Operational Bottlenecks

This table effectively illustrates the practical application of EviSmart's technology by linking common, relatable dental lab pain points directly to specific modules and features within the EviSmart platform. This problem-solution focus makes the benefits of EviSmart tangible for lab owners and managers, demonstrating how the system works to alleviate specific operational challenges. It reinforces EviSmart's role as a case study in this report by providing detailed evidence of its approach to solving industry-wide issues. The table also implicitly highlights EviSmart's dual strengths: the application of AI for intelligent decision-making and process optimization, and its platform-based approach to achieving connectivity across a typically fragmented technological landscape.

Section 5: Real-World Implementation: Navigating Challenges When Assisting Labs Automate

The journey of implementing workflow automation in a dental laboratory is a collaborative effort between the lab and the automation solution provider. From the perspective of a provider assisting labs in this transition, several recurring challenges emerge that require proactive strategies and careful management. These challenges often transcend purely technical issues, delving into organizational culture, existing processes, and human factors.

5.1 Initial Assessment and Expectation Management

A common initial hurdle is managing the laboratory's expectations regarding the outcomes, speed, and ease of automation implementation. Labs, eager for improvements, may sometimes possess unrealistic expectations, perhaps underestimating the internal changes and preparatory work required on their part. They might envision an instant transformation or overestimate what current automation technology can autonomously achieve without significant human oversight or process adjustment.

Therefore, a critical first step for an automation provider, as exemplified by EviSmart's approach of "We Map Your Workflow" and "We Identify Your Bottlenecks", is to conduct a thorough assessment of the lab's existing workflows, technological infrastructure, staff skill levels, and specific pain points. This diagnostic phase is essential for setting realistic, achievable goals and developing a clear, phased roadmap for automation. It also involves educating the lab leadership and team about the true capabilities and limitations of the proposed solutions, ensuring that expectations are aligned with what can be practically delivered.

5.2 Overcoming Resistance to Change and Fostering Buy-in

Resistance to change from laboratory staff, particularly experienced technicians, is one of the most significant and frequently encountered barriers. This resistance often stems from fears of job displacement, concerns about their ability to learn and adapt to new, complex digital systems, or a general skepticism towards the efficacy of new technologies compared to tried-and-true manual methods. Lack of clear leadership alignment or insufficient championing of the automation initiative from the lab's management can further exacerbate this resistance and stall progress.

An automation provider plays a crucial role in helping the lab navigate these human factors. This involves advising lab leadership to emphasize that automation is intended to augment and enhance the skills of technicians, not to replace them entirely. Clear, consistent, and transparent communication about the project's goals, benefits for both the lab and the employees, and the implementation plan is vital. Involving staff in the technology selection and workflow redesign process can foster a sense of ownership and reduce apprehension. Highlighting how automation can eliminate tedious, repetitive tasks, thereby freeing up technicians to focus on more engaging, creative, and higher-value aspects of their work, can also help build buy-in. Identifying and empowering internal champions who are enthusiastic about the new technology can also be an effective strategy to drive adoption from within.

5.3 Data Quality and Preparation: The Foundational Hurdle

The success of any automation initiative, especially those involving AI, is fundamentally dependent on the quality of the input data. Automation providers frequently encounter situations where laboratories struggle with inconsistent, incomplete, or poorly structured data. This is particularly challenging in dental labs, as a significant portion of this data (e.g., digital impressions, prescriptions) originates from external sources—the dental clinics—whose quality control may vary. Attempting to automate workflows using poor-quality input data will invariably lead to substandard outputs, errors, and inefficiencies, thereby undermining the goals of the automation project.

Providers like EviSmart address this by incorporating tools such as EviSmart QC, which uses AI to pre-filter incoming cases and flag data quality issues before they enter the production pipeline. Beyond providing technological solutions, assistance often involves advising labs on the critical importance of establishing robust data governance policies and stringent data quality standards. This includes implementing feedback mechanisms to communicate data quality issues back to the referring dental clinics, thereby fostering an improvement in the quality of data received over time. A key part of the consultation process is often to emphasize that data cleansing, standardization, and governance are essential prerequisites that must be addressed before or in parallel with full-scale automation deployment.

5.4 Technical Integration with Diverse Existing Systems

Dental laboratories typically operate with a diverse array of equipment and software acquired over time from different vendors. This often includes various types of intraoral and desktop scanners, CAD software packages, milling machines, 3D printers, and laboratory management systems, many of which may be closed systems or possess limited Application Programming Interfaces (APIs) for external communication. Achieving seamless technical integration between these disparate components and the new automation platform is a complex and often underestimated challenge.

For an automation provider, especially one like Evident that emphasizes universal compatibility, a significant portion of the implementation effort involves meticulously mapping data flows between the lab's existing systems and configuring the automation platform to act as a central orchestrator or hub. This is where the provider's expertise in systems integration and understanding of various dental technologies becomes paramount, as highlighted by EviSmart's claim: " Intelligently Connecting Dental Workflows ". Practical challenges encountered during this phase can include dealing with outdated software versions on legacy equipment, a lack of cooperation from third-party vendors whose systems need to be integrated, unexpected limitations in available APIs, or the need to develop custom connectors or middleware to bridge communication gaps.

5.5 Training and Skill Development: Ensuring User Adoption

Even the most sophisticated automation system will fail to deliver its potential benefits if the laboratory staff are not adequately trained to use it effectively. Technicians and administrative personnel often need to learn new software interfaces, adapt to digitized processes, and sometimes fundamentally change their established ways of working. Insufficient or ineffective training is a common reason for the underutilization of new technologies or their incorrect application, which can lead to errors, inefficiencies, and frustration.

A key responsibility of the automation provider is to deliver comprehensive onboarding and tailored training programs for all relevant EviSmart platform modules and functionalities, as suggested by the "Designed for quick and easy onboarding" philosophy. This often involves more than just initial software training; it extends to providing ongoing support, accessible learning resources, and potentially advanced training as the lab's use of the system matures. Providers may also advise labs on implementing a phased training approach, perhaps starting with a group of "super-users" or internal champions who can then assist their colleagues, or focusing training on specific modules as they are rolled out. The goal is to build confidence and competence among users, ensuring they can leverage the new tools to their full potential.

5.6 Managing Workflow Adjustments and Initial Disruptions

The introduction of automation inevitably leads to adjustments in established laboratory workflows. These changes, while ultimately beneficial, can cause temporary disruptions and, in some cases, an initial dip in productivity as staff adapt to new processes and tools. Managing this transition period effectively is crucial for the long-term success of the automation project.

Automation providers often advise a phased rollout strategy for new systems and workflows, rather than a "big bang" approach that changes everything overnight. This allows the lab to implement and stabilize changes in one area before moving to the next, minimizing widespread disruption. During this transition, the provider offers critical support by helping the lab redefine roles and responsibilities where necessary, troubleshooting any issues that arise with the new systems or processes, and working collaboratively with the lab team to optimize the newly automated workflows for maximum efficiency and effectiveness.

The challenges encountered when assisting labs to automate are deeply rooted in the socio-technical nature of these environments. It's rarely just about installing new software or hardware; it's about facilitating a significant transformation in how people work, how information flows through the organization, and how the lab interacts with its external partners, particularly dental clinics. Success in this endeavor hinges on a strong partnership approach between the laboratory and the automation solution provider, characterized by open communication, robust and continuous training, flexible and adaptive strategies, and a shared commitment to achieving the desired outcomes. The emphasis by solutions like EviSmart on connecting existing systems suggests that integration complexity and data handling are very common and significant challenges that they are specifically designed to address. Similarly, the development of AI-driven QC modules indicates that poor input data quality from clinics is a frequent problem requiring automated, pre-emptive solutions.

Section 6: Charting the Course: Strategic Recommendations for Dental Labs

Embarking on the journey of workflow automation requires dental laboratories to adopt a strategic and methodical approach. Simply acquiring new technology is insufficient; success depends on careful planning, diligent execution, and a commitment to continuous adaptation. The following recommendations provide a framework for labs to navigate this transformative process effectively.

6.1 Conduct a Thorough Self-Assessment and Define Clear Objectives

Before any investment in automation technology is made, a laboratory must undertake a comprehensive self-assessment. This involves meticulously evaluating current workflows to identify specific bottlenecks, inefficiencies, and pain points. It is crucial to quantify these issues where possible—for example, by measuring current remake rates, average turnaround times for different types of restorations, labor costs associated with specific manual tasks, or material wastage.

Based on this assessment, the lab should then define clear, measurable, achievable, relevant, and time-bound (SMART) objectives for its automation initiative. Vague goals like "improve efficiency" are less effective than specific targets, such as "reduce the remake rate for zirconia crowns by 5% within 12 months," "shorten the average turnaround time for single-unit crowns by 24 hours," or "increase overall case capacity by 15% without increasing staffing levels." These objectives must be intrinsically aligned with the laboratory's broader business goals, such as increasing profitability, expanding market share, or enhancing client satisfaction.

6.2 Develop a Phased Implementation Strategy: Start Small, Scale Smartly

Attempting to automate all laboratory processes simultaneously—a "big bang" approach—is often risky and can lead to significant disruption and potential failure. A more prudent strategy is to adopt a phased implementation plan. This involves starting with pilot projects that focus on specific areas of the workflow known to have high potential for return on investment or those that represent significant current pain points. For example, a lab might begin by automating its digital impression intake and initial quality control, or by implementing automated nesting software for its milling machines.

The learnings and successes from these initial pilot projects are invaluable. They provide practical insights into the technology's performance in the lab's specific environment, help identify unforeseen challenges, and allow staff to gain confidence with new systems on a smaller scale. These experiences should be used to refine the overall automation strategy, adjust timelines, and inform training needs before embarking on wider rollouts. Once initial phases are successful and stable, the lab can then gradually expand automation to other departments, product lines, or more complex processes, scaling its efforts smartly and sustainably.

6.3 Prioritize Investments and Choose the Right Solutions & Partners

Given that financial resources are often constrained, laboratories must prioritize their automation investments. Focus should be placed on solutions that address the most critical bottlenecks identified during the self-assessment phase and those that offer the best potential for tangible returns in the shortest feasible timeframe.

When selecting technology, it is essential to choose solutions that are not only effective for current needs but are also scalable to accommodate future growth, interoperable with existing and future systems, and supported by reputable vendors who offer robust customer service, training, and technical assistance. For labs struggling with a fragmented technological landscape, platforms like EviSmart, which emphasize their ability to connect and integrate existing disparate systems, may offer a particularly attractive value proposition.

The evaluation of potential vendors should extend beyond the technical specifications of their products. It is equally important to assess their understanding of dental laboratory workflows, their track record in the industry, and their commitment to providing ongoing implementation support and partnership. A vendor who acts as a true partner, understanding the lab's unique challenges and goals, will be far more valuable than one who simply sells a product.

6.4 Invest in Data Governance and Quality from Day One

As automation heavily relies on data, establishing strong data governance and ensuring high data quality from the outset is non-negotiable. This involves developing and implementing clear protocols for data capture (e.g., standards for incoming digital impressions), data management (storage, backup, archiving), data security (HIPAA compliance, access controls, encryption), and data integrity.

Since a significant portion of input data comes from external dental clinics, laboratories must also proactively work with their clients to improve the quality of incoming digital impressions and prescriptions. This might involve providing feedback on scan quality, offering training or guidance to clinic staff on best practices for digital impression taking, or implementing systems (like EviSmart QC) that provide automated feedback on submitted cases. Investing in data quality is an investment in the reliability and effectiveness of the entire automated workflow.

6.5 Foster an Automation-Ready Culture: Invest in Your People

Perhaps the most critical factor for successful automation is fostering an organizational culture that is receptive to change and embraces new technologies. This begins with strong leadership that clearly and consistently communicates the vision, purpose, and benefits of automation to all staff members.

A significant investment in people is required. This includes providing comprehensive training and upskilling opportunities to equip technicians and administrative staff with the competencies needed to operate and manage the new digital tools and workflows. As automation takes over routine tasks, roles may need to be redefined, allowing skilled technicians to focus on higher-value activities such as complex case design, quality assurance, client communication, and problem-solving.

Involving technicians and other staff members in the selection and implementation process can be highly beneficial. This fosters a sense of ownership, reduces fear and resistance, and allows the lab to leverage the practical knowledge of its team in designing more effective automated workflows. Encouraging a mindset of continuous learning, experimentation, and adaptation is also crucial, as the technology and the lab's needs will continue to evolve.

A successful automation strategy is, therefore, a holistic endeavor. It is as much about thoughtful strategic planning, proactive change management, and investment in human capital as it is about the selection and implementation of advanced technology. Laboratories that approach automation with this comprehensive perspective, addressing not only the technical aspects but also the crucial organizational and human factors, are far more likely to overcome the inherent challenges and realize the profound benefits that these transformative technologies offer.

Section 7: The Future is Automated: Sustaining Growth and Competitiveness

The adoption of workflow automation is not merely a trend but a foundational shift in how dental laboratories will operate and compete in the future. As technology continues to advance and market expectations evolve, the ability to leverage automation effectively will become increasingly critical for sustaining growth, enhancing service quality, and maintaining a competitive edge.

7.1 The Dental Lab of Tomorrow: An Integrated, Intelligent Hub

The vision for the dental laboratory of tomorrow is one of a highly efficient, agile, and data-driven entity. In this future state, AI and automation will seamlessly handle the majority of routine, repetitive, and labor-intensive tasks—from initial case intake and quality control of digital impressions to the basic design of restorations and the operation of manufacturing equipment. This will free up highly skilled dental technicians to concentrate on the most complex aspects of their craft: intricate aesthetic design, advanced problem-solving for challenging cases, personalized client communication and consultation, quality assurance oversight, and driving innovation in materials and techniques.

This future lab will be characterized by seamless digital connectivity, not only internally between its various departments and systems but also externally with its network of dental clinics and material suppliers. Real-time collaboration platforms will enable instant communication and data exchange, facilitating more responsive service and optimized supply chains. Data analytics, fueled by the wealth of information captured through digital workflows, will provide deep insights into operational performance, client preferences, and market trends, enabling more informed strategic decision-making.

7.2 Continuous Improvement and Adaptation: Staying Ahead of the Curve

It is crucial to recognize that implementing workflow automation is not a one-time project with a defined endpoint. Rather, it is an ongoing process of continuous improvement, refinement, and adaptation. The landscape of digital dental technology, AI, and automation is evolving at a rapid pace. New tools, software updates, improved algorithms, and entirely novel approaches will continue to emerge.

To remain at the forefront and sustain the benefits of automation, laboratories must cultivate a culture of agility and innovation. This involves regularly reviewing key performance indicators (KPIs) to assess the effectiveness of current automated systems, actively soliciting feedback from staff and clients to identify areas for improvement, and staying informed about new technological developments and automation opportunities relevant to the dental lab industry. The projected significant growth of the global digital dentistry market, estimated to expand from USD 7.2 billion in 2023 to USD 12.2 billion by 2028 with a compound annual growth rate (CAGR) of 10.9%, underscores the continuous technological evolution and the expanding opportunities within this space. Labs that become static after an initial phase of automation risk falling behind as technology and competitors advance.

7.3 Conclusion: Committing to Automation as a Strategic Imperative

In conclusion, the journey towards comprehensive workflow automation presents both significant challenges and transformative opportunities for dental laboratories. The hurdles—financial, technological, data-related, and human-centric—are not insignificant and require careful strategic planning, diligent execution, and a commitment to ongoing adaptation.

However, the benefits that accrue from successfully navigating these challenges are profound. Dramatically enhanced efficiency, consistently higher quality restorations, significantly reduced turnaround times, substantial cost savings, and strengthened collaborative partnerships with dental clinics are all achievable outcomes. These advantages translate directly into improved profitability, greater client satisfaction, and a stronger competitive position in the marketplace.

Solutions like EviSmart serve as important examples, demonstrating that the technological means to connect disparate systems, leverage artificial intelligence for smarter workflows, and achieve a higher degree of automation are increasingly available and effective. They offer a pathway for labs to overcome the fragmentation that has long characterized dental technology adoption.

Ultimately, for dental laboratories aiming to thrive in the modern, digitally driven dental industry, embracing workflow automation is no longer a discretionary choice but a strategic imperative. The commitment to this evolution, approached with foresight and a holistic understanding of its implications, will be a defining factor in the long-term success and sustainability of dental laboratories in the years to come. The future of the dental lab is undeniably automated, and those who proactively chart their course in this direction will be best positioned to lead and innovate.